Thanks to Brian Tanner for this guest blog

The influence of size/ spaciousness on the cost of ship construction and since parametrics are generally weight based how can an estimator allow for changes in ship density in the early design stages? ...

In this month’s (May 2016) issue of ‘Warships International Fleet Review’ there is an article entitled ‘Why Size Matters’ which suggests that warship hulls should be built large enough to be capable of housing two generations of technology within its lifetime. This would be achieved by a mid-life upgrade without ship fitting difficulties.

It goes on to say that a larger hull results in a more seaworthy ship and mentions the later batches of Type 42 destroyer and Type 22 frigates as examples stating “a few hundred thousand pounds worth of steel (in the Batch 1 ships) was all that was necessary to turn a poor sea boat into something better” with the added advantage of no redesign costs for later batches of the class. As regards the Type 42 there is an interesting letter in the May 2016 issue of ‘The Marine Professional’ referring to the design being cost constrained while estimated solely by weight based parametrics.

And the point of this article: the influence of size/ spaciousness on the cost of ship construction and since parametrics are generally weight based how can an estimator allow for changes in ship density in the early design stages?

The first question is undoubtedly “What evidence is there that a spacious design is more economical to build?”

Firstly, at the ASNE Engineering the Total Ship (ETS) Symposium, Falls Church, VA, 24 September 2008 a paper titled “Damen Schelde Naval Shipbuilding, Damen’s philosophy: Standardized Patrol Boats and Naval Vessels” was presented by Jaap L. Gelling MSc., Damen Shipyards Gorinchem and Leon Goossens MSc., Damen Schelde Naval Shipbuilding. Reproduced below is one section of the paper dealing with the realised benefits of a spacious hull:

Oversized hulls

Of the Damen Stan Patrol range and the Damen Fast Crew Supplier range, a major part is of “Sea Axe” design (Axe Bow Concept) shown in Figure 1, and one ship is designed to the Enlarged Ship Concept (predecessor of the Sea Axe). These designs make use of an oversized slender hull to improve seakeeping characteristics.

Figure 1: Damen Stan Patrol 5009

On first sight, the oversized hull might be considered a disadvantage, as it will be heavier and more expensive. The reality however is considerably different:

- The hull of a patrol boat represents only approx. 20% of the total building cost. An oversized hull of 20% in length, in principle will increase the total building cost only by approx. 3-4%. For naval vessels this difference is even smaller due to the costly military equipment and systems.

- As the oversized hull is relatively empty, the limited extra cost for the larger hull is easily recovered by significant savings on labour for installation of equipment. This was already confirmed during the outfitting of the first series of Stan Patrol 4207’s which took significantly less labour hours than expected.

Figure 2: HMNZS Wellington

Secondly, VARD, previously STX Canada Marine, have designed a series of successful Offshore Patrol Vessels in their 07 series. 1 The series began with the PV75 ‘Vigilant’ for the Coast Guard of Mauritius built in Chile in 1994. 2 This vessel was based on the 72m Canadian Coast Guard vessel Leonard J Cowley. Subsequent vessels include the 80m Roisin class (2 off) and the 90m Samuel Beckett class 3 (3 off) for the Irish Naval Service together with the 85m Protector class 4 (2 0ff) for the Royal New Zealand Navy shown in Figure 2. The VARD website claims the design philosophy to:

- Engineer greater seaworthiness at higher speeds in a slightly larger but easier to build vessel

- Design higher internal volume, easier to outfit spaces.

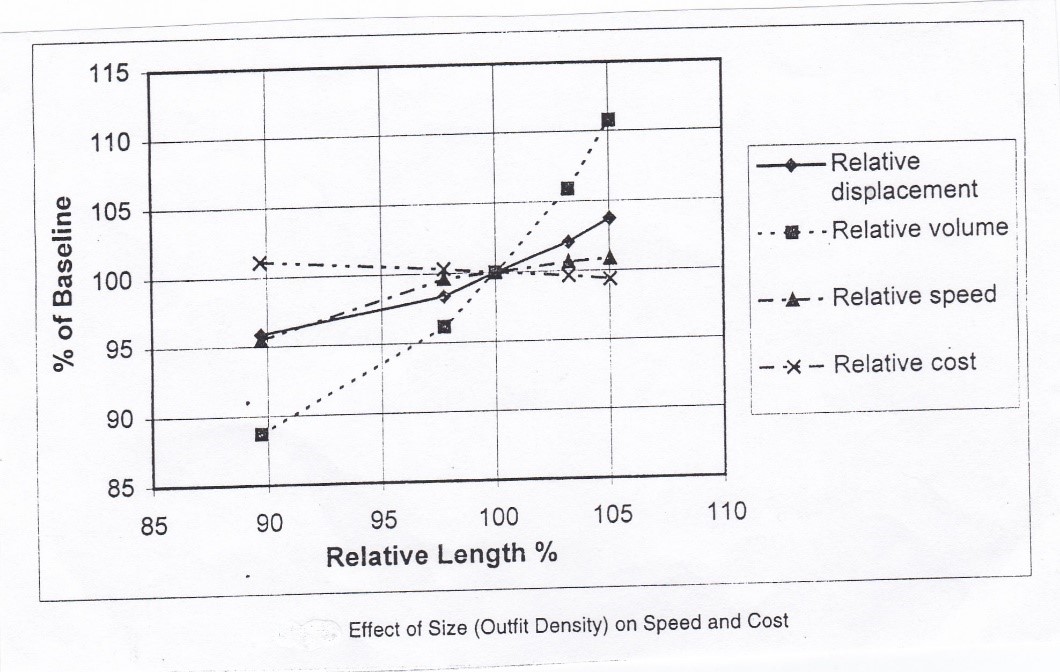

Thirdly, Andrew Humphries in his April 1995 PhD thesis: ‘The Development and Application of Warship Cost Estimating Methods’ continued the Vosper Thorneycroft interest in outfit density 5 and at the RINA Warship 98 conference R.D. Mulligan and M D Courts of the company presented a paper ‘Corvette Design Considerations’ which included Figure 3, presumably based on Humphries research.

Figure 3: Effect of Outfit Density on Size and Cost

This demonstrates that some increase in ship size, while retaining the same equipment and systems, has a small but advantageous effect on ship costs. But there has to be a limit, but what is it? From work I did in CAAS in the early ‘noughties’ existing warships have a density variation of some ±15% and the overall effect on UPC would be ±1%.

Fourthly, are there any other examples?

In Denmark the Odense shipyard built the Absalon class of flexible support ships and in Janes Navy International of 1st July 2004 with delivery of the first ship imminent the company commented:

“It has been an interesting experience and a challenge for us.” He adds “The equipment density is far greater than we are used to with commercial ships. Coordination and sequencing of outfitting has been more challenging than we originally anticipated, and we have exceeded our man-hours target on the first ship. However, we are improving productivity as we go up the learning curve and we are seeing benefits on the second ship.”

An advertising pamphlet from Roxtec Seals states “The new Danish flexible support ships in the Absalon class start out as civilian ships at the Odense Steel Shipyard. They are then moved to the Korsoer and Frederikshavn Military Naval Bases for retrofit of military systems and equipment. This addition includes the routing of extensive amounts of new electrical cables and piping throughout different zones and hazardous areas onboard.”

Therefore suggesting that the Odense shipyard statement does not scope the total activity for outfitting a naval vessel.

A fifth but converse example is the US Navy DDG51 class which were reduced in size. The following is an extract from a January 2012 GAO report (GAO- 12 – 113) on the Arleigh Burke Destroyers (i.e. DDG51 class):

Figure 4: DDG 51 Flight 1

DDG 51 is already the most dense surface combatant class; density refers to the extent to which ships have equipment, piping, and other hardware tightly packed within the ship spaces. According to a 2005 DOD sponsored shipbuilding study, the DDG 51 design is about 50 percent more dense and complex than modern international destroyers.

Report Footnote: Measured in terms of pounds of weight per cubic foot (lbs/cf), the DDG 51 class has an outfit density of close to 8 lbs/cf which is more than the DDG 1000 and FFG 7 classes, which are approximately 7 lbs/cf, and the CG 47 class, which is approximately 7.5 lbs/cf.

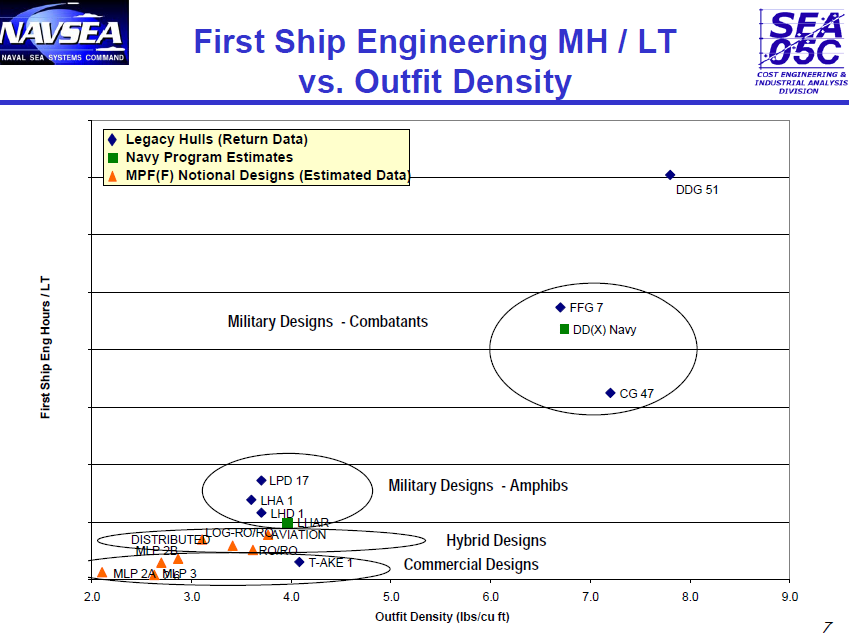

Figure 5: First Ship Engineering MH / LT vs. Outfit Density

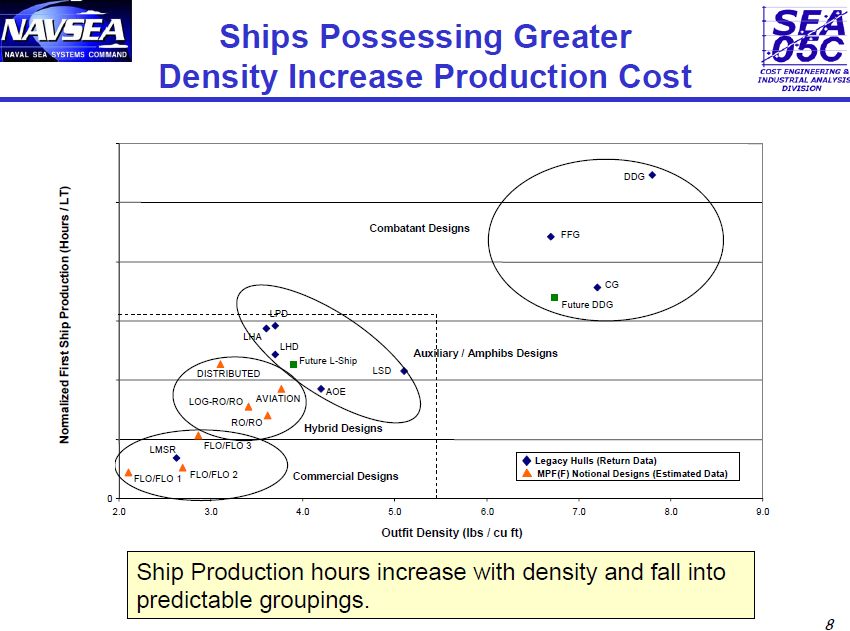

While the increase in density of some 7% to 14% - depending on the comparator - has an impact demonstrated by these slides from NAVSEA 05C, the Cost Engineering and Industrial Analysis Division of the USDoD NAVSEA organisation.

Figure 6: Ships Possessing Great Density Increase Production Cost

Japan and South Korea have built their own versions of the DDG 51, but with larger dimensions as tabled here:

Figure 7: DDG 51 variants and comparisons

| Ship | DDG51 Flight 1 | JDS Kongo | KDXIII |

| Length oa m | 152 | 161 | 166 |

| Length wl m | 142 | ||

| Beam max m | 20 | 21 | 21 |

| Beam wl m | 18 | ||

| Depth m | 12.7 | ||

| Volume m3 | 32,461 | ||

| Lightship Weight Te | 6,671 | ||

| Standard Displacement Te | 7,500 | 8,500 | |

| Full Load Displacement Te | 8,362 | 9,485 | 11,000 |

A June 2014 MIT paper titled ‘Improving the Parametric Method of Cost Estimating Relationships of Naval Ships’ by Ungtae Lee examined the parameters of ‘Electric Power Density’ (EPD) and ‘Outfit Density’. The EPD parameter was introduced by RAND in the 2006 report ‘Why Has the Cost of Naval Ships Risen?’ It is defined as:

“Electrical power generation capacity in kW divided by Lightship Weight”

While Outfit Density is defined as:

Weight of all interior systems and equipments divided by ship volume

Which can be determined by:

Def Stan 02-163 Σ (Weight Groups 2 to 7) divided by ship volume.

The data used to determine the new Cost Estimating Relationship was the Final “end unit cost” which includes all Government-Furnished Equipment and contractor furnished equipment. 6In both reports the cost of a ninth ship is used 7 and the comparable parametric equations are:

MIT Paper:

Ln(Cost)9 = 0.626*Ln(LSW) 8 + 1.05*Ln(EPD) + 1.129

While RAND produced the relationship:

Ln(Cost)9 = 0.947*Ln(LSW) 9 + 0.943*Ln(EPD) + 11.50 + Qualitative factors for auxiliary vessels or submarines.

The 2014 MIT paper made no distinction between surface combatants and other very different vessels so the RAND relationship is preferred and demonstrates a near linear relationship with build weight and power density.

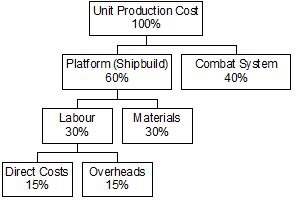

The MIT paper includes the conclusion: ‘Additional variables such as outfit density and shaft horsepower did not statistically improve the CER.’ which is in keeping with other evidence. A typical breakdown of a surface combatant UPC is shown here and demonstrates that labour is just 15% of the UPC. Outfit Density is claimed to save on labour, the main benefit being in seakeeping and in-service support, the NAVSEA plots demonstrating a labour increase of 12% to 16% for DDG-51 leading to a 2½% increase in UPC in keeping with the VT estimate and probably less as the denser hull is slightly lighter. Looked at in reverse, a less dense but slightly larger vessel will be cheaper by a similar margin.

Figure 8: Unit Cost Breakdown

So, the answer to the first question has to be that favourable evidence does exist. That leads to a second question: Given that a parametric estimate will be based on existing vessels/ data, how does the estimator adjust an estimate for varied outfit density?

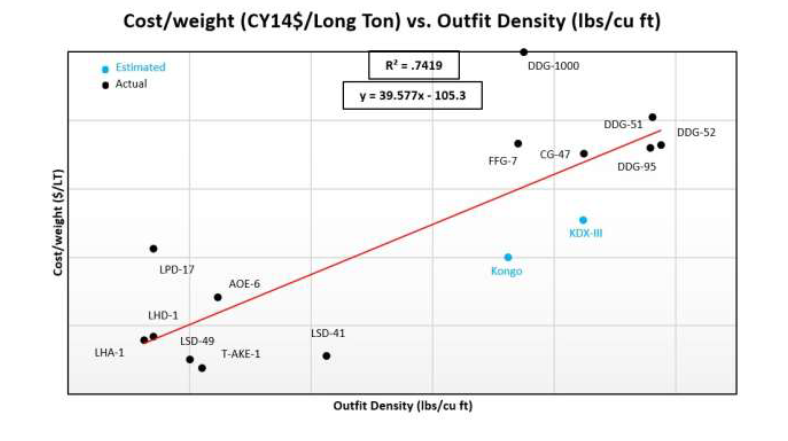

A search of public domain information on the internet has not produced a definitive tool/ relationship. The MIT paper has the graph, shown in Figure 7, of cost per ton versus outfit density which seems to contradict the finding that outfit density had no effect on the CER. One explanation can be that the graph consists of two groups of dissimilar vessels so its use is questionable.

Figure 9: Cost / Weight ($/Long Ton) vs. Outfit Density (lbs/ cu ft)

While a SPAR Associates paper EM-CM-001 ‘Estimating Design & Construction’ January 2010 includes a graph where the density factor was calculated for a selection of ships, both commercial and naval the density being defined as:

Density Factor = Σ(SWBS 200 – 700 MTON weights)/ Ship M3 Displacement

Figure 10: Tracking Labour Hours per MTON vs. Density "1" Factor

Which is more a ratio of outfit to total weight and not relevant to the current consideration.

So, while some evidence exists to demonstrate that a spacious ship will cost no more than, and perhaps a little less than, a cramped design there is no rigorous cost estimating relationship to modify an estimate based solely on weight parametrics that make no allowance for outfit density.

The SDSR 2015 which reduced the number of Type 26 frigates from 13 to 8 also stated:

“We will also launch a concept study and then design and build a new class of lighter, flexible general purpose frigates”.

Hopefully, the experience of the Type 42 destroyer will not be repeated and that the ‘lighter’ warship will not be achieved by a dense equipment density that at the conclusion of construction will be found to have given no cost benefit and prove expensive and difficult to operate and maintain. One example of a larger hull with lower outfit density does exist, albeit for a different reason, and that is the South African Valour class frigate. It was initially described as a ‘Patrol Corvette’ which was a frigate hull for good seakeeping in the southern oceans with a corvette’s armament although significant upgrades were originally planned and have subsequently been achieved.

1 Source: http://vardmarine.com/vessel-design-portfolio/offshore-patrol-vessels/

2 The vessel developed a serious problem on its port shaft in May 1997, a year after commissioning. The Naval Dockyard Mumbai brought it under tow to the yard for repair. The starboard shaft was also found to be weak and several other systems on-board sub-standard.

3 These are 10m longer and 0.3m deeper than the Roisin class reportedly to improve seakeeping.

4 Public domain information suggests that the ships suffer from a weight problem allegedly due to the introduction of an ice strengthened belt in the hull.

5 RINA Paper ‘A Family of Warships’ by P.J. Usher OBE C.Eng. RCNC and A L Dorey C Eng. read on 29th April 1981

6 Usually described at the Unit Production Cost (UPC).

7 Presumably as the learning curve for labour will to all intents become level.

8 LSW is Lightship Weight, i.e. Basic Weight or Build Weight

9 LSW is Lightship Weight, i.e. Basic Weight or Build Weight